Manufacture process

Daegu New Materials Co., Ltd.

Trends of Tungsten Carbide Material Industry

✔ Our company's main product, the tungsten carbide material industry, plays a pivotal role in the national economy and has significant ripple effects as a base industry, while at the same time showing the level of the national industry.

- ▪️ The downstream industries include the automobile parts industry, electrical and electronic parts industry, shipbuilding equipment industry, machinery parts industry, Die & Mold Industry, and tool industry, and the use of high-hardness new material parts to improve wear resistance is rapidly increasing.

- ▪️ As demand for precision Die & Mold, and cutting tools increases in forward industries such as automobiles, aviation, shipbuilding, energy, and semiconductor industries, advancement of related technologies and simultaneous growth of the market is expected.

- ▪️ It is a basic industry that determines the quality and productivity of parts and products applied to national strategic industries (automobiles, displays, semiconductors, electrical, and electronics) and main industries (transportation machinery and mobile industries).

Downstream Industry of the Tungsten Carbide Material Industry

Tungsten Carbide Material Industry

- ▪️ Raw Material Powder Synthesis Technology

- ▪️ Sintering Technology

- ▪️ Heat Treatment Technology

- ▪️ Coating Technology

- ▪️ Material Composition Design Technology

- ▪️ Precision Machining Technology

- ▪️ Raw Material Mixing Technology

- ▪️ Tool Grinding Technology

National Basic Industry

-

Automobile Industry

Precision Machining of Engines, Transmissions, Pumps, Brakes and more -

Machinery Industry

Precision Machining and Assembly of Machine Parts -

Aviation Industry

Precision Machining and Manufacturing of Engines, Transmissions, Brakes and more -

Electrical and Electronic Industry

Electrical Parts Process, Drawing Process, Copier, Video Drum, Cathode Ray Tube, PCB substrate Machining -

Die & Mold Industry

Die & Mold Imitation Machining, Curved Surface Machining, General Purpose Machining of Die & Mold Steel and more -

Construction Industry

Interior and Exterior Construction, Roads, Ports, Construction, Bridges, Structure Dismantling -

Semiconductor Industry

Semiconductor Wafer Cutting, Precision Machining of Media -

Materials and Steel Industry

Steel Drawing, Cutting, Rolling, and New Material Machining -

Jewelry, ceramic, glass industry

Diamond, Cubic and more Jewelry Machining, Ceramic, Glass Machining -

Stone and Mining Industry

Plate and Jewelry Machining, Quarry Management, Mine Drilling, Exploration -

DIY Industr

Tools for General Household Fabrication, Repair and Assembly -

Private Industry

Drilling Shop, Wooden Construction, Professional Repair Tools

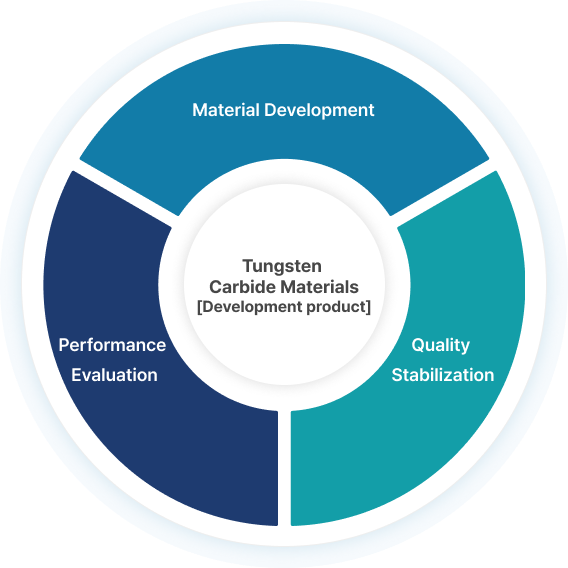

Progressive System for R&D of Tungsten Carbide Materials

- 1. Development of Ultra-fine WC Powder Manufacturing Proccess & Method

- 2. Improvement of Mechanical Properties (Hardness, Transverse Rupture Strength)

- 3. Appropriate Elemental Composition and Metallic Structure Analysis

Development of Tungsten Carbide Materials Suitable for Customer Needs

- 1. Performance Evaluation of Materials (Life Evaluation)

- 2. Development of Tungsten Carbide Materials Suitable for Customer Needs

- 3. Tungsten Carbide Structure with Uniform Particle Size and Distribution

Performance Evaluation of Developed Materials

- 1. Establishment of Manufacturing Method of Tungsten Carbide Materials

- 2. Management of Various Factors

- 3. Establishment of Customer-tailored Material Development and Commercialization Plan

Establishment of Quality Stabilization